Injection molding of precision plastic parts in the healthcare industry requires, among other things, state-of-the-art mold technology and quality for sustainable production. Injection molding production at Wirthwein Medical GmbH & Co. KG in Mühltal runs on highly automated and state-of-the-art machines and systems; high-performance molds with up to 96 cavities are used. As a full-service supplier, optimal manufacturing solutions for controlled production are created together with the customer..

The plastics expert Wirthwein Medical GmbH & Co. KG can look back on decades of experience in projects involving large-scale production of miniature parts. There are several factors to consider and challenges to overcome in this application area. Together with the customer, Wirthwein Medical develops an optimal tooling and manufacturing concept, which is designed to meet the challenge of large-volume serial production. Often, the positioning and design of the injection point as well as the demolding of the parts is challenging. Here, sometimes different interests and specifications are opposed to each other, which are discussed in detail with the customer and implemented in an optimal mold concept.

Innovative mold concept

The larger the quantities and the smaller the plastic components, the more demanding is the injection mold. The complexity and challenges of the plastic components lie in the details. The definition and design of the gating system is important for the most homogeneous and uniform filling of the cavities. The consistent quality of the gating point and clean break-off are often basic requirements for subsequent processes, such as on assembly lines or filling lines. "It is important to us to continue to expand our expertise over generations of molds, so that our experience from series production is incorporated into new concepts together with further technical developments," says Thorsten Kellner, Head of Development and Project Management at Wirthwein Medical GmbH & Co. KG.

Synchronous needle actuation plate for a clean drop

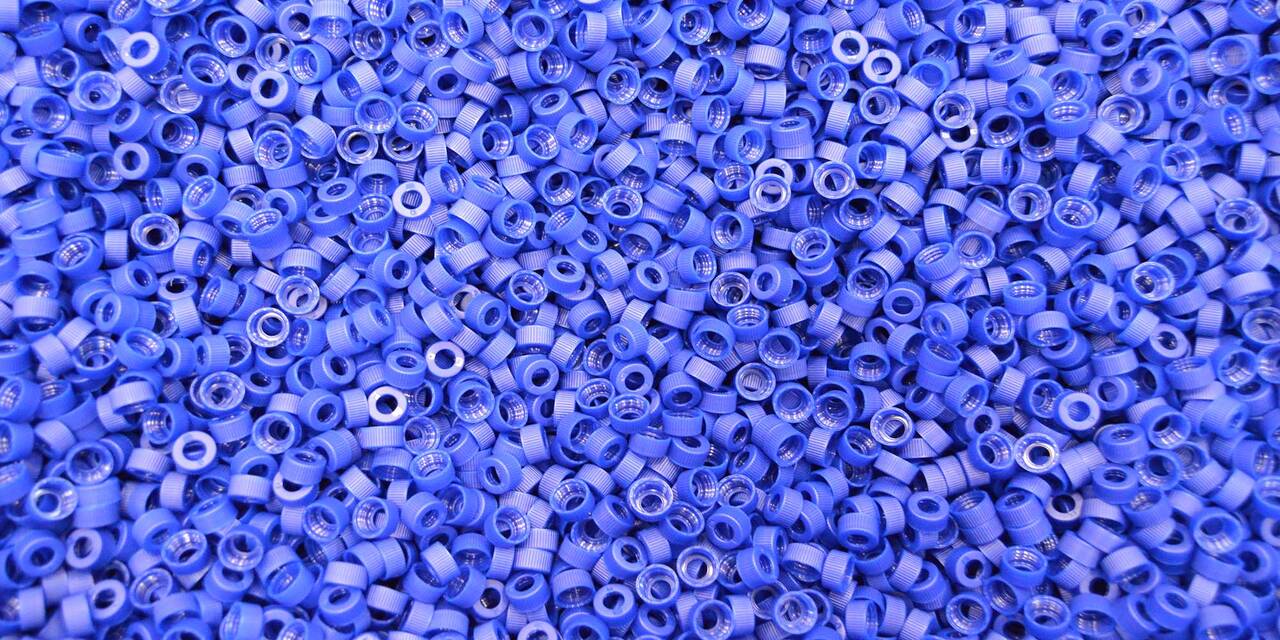

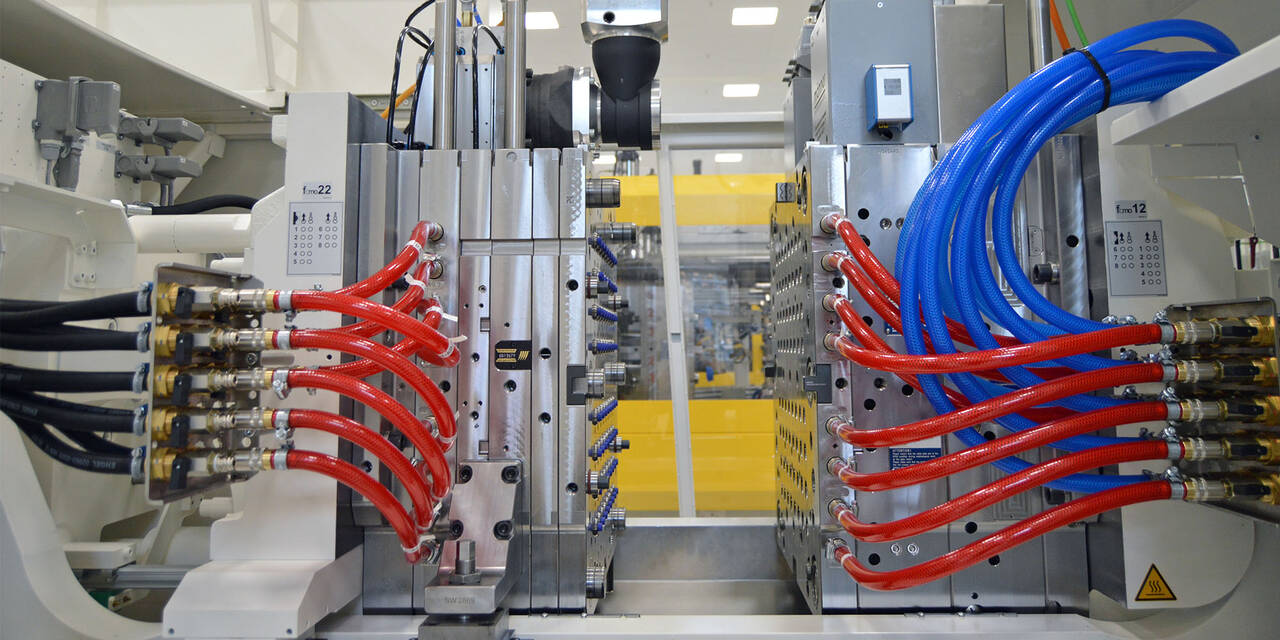

For the production of screw caps used in the diagnostics sector, for example, an innovative 64-cavity injection mold was chosen as an economical and production-efficient solution. Two servo-electric drives are the special feature of the mold. One drive is used for the unscrewing of an internal thread. The thread unscrewing unit can be precisely controlled by the servo motor drive. The screw caps are unthreaded faster compared to mechanical solutions and the process can be controlled and optimized much more precisely and accurately.

The needles of the hot runner are also controlled by servo motor drive to ensure synchronous movement of the needles, which is reflected in a uniform filling pattern and perfect process control. Maximum part quality and repeatability is achieved through this process.

Furthermore, the plastics expert Wirthwein puts a special focus on the uniform demolding of the plastic components during product development to ensure an optimal drop pattern of the components.

The company also focuses in particular on the maintenance of series injection molds in its in-house mold shop and mold maintenance. To ensure high mold availability, fully qualified spare parts packages are provided on a risk basis. This reduces downtime to a minimum and ensures delivery reliability to the customer.

Other important factors in production

In addition to the mold, other factors must be taken into account for efficient production in order to cope with the high volumes and ensure overall system effectiveness. The reliability and repeatability of the injection molding machine and peripherals is another crucial aspect. By monitoring the media supply, which is also integrated into the machine's control system, malfunctions can be eliminated quickly, thus minimizing scrap. Exact and consistent color setting for the product is achieved by means of gravimetric batch feeding with maximum dosing accuracy. Dedusting of the raw material to avoid foreign material inclusions or inclusions in the end product, which can lead to undesirable contamination, is also used at Wirthwein Medical GmbH & Co. KG. Loose parts, such as dust or fluff, are separated into a dust collection container and thus sorted out before the plastics are processed.

"One aspect that should not be underestimated is the layout and design of the further production environment. This includes, for example, conveyor belts, interfaces to the clean room, packaging, and an ergonomic and optimally designed workplace so that the plastic components are traceable and clearly marked and labeled," explains Production Manager Michael Lergenmüller finally.